Experimental Techniques

Experimental techniques, i.e., Modal Analysis (MA) and Operational Deflection Shapes (ODS) are initial diagnostic techniques employed to assess the dynamic behavior and troubleshoot potential issues in a structure before initiating the process of Structural Dynamic Modification (SDM).

Techniques

Results obtained from Modal Analysis (MA) and Operational Deflection Shapes (ODS) are compared together during the troubleshooting process.

Modal Analysis

Experimental Modal Analysis (EMA) is commonly performed as the modal analysis method. It involves exciting the structure with controlled forces or inputs and measuring its dynamic response using sensors. By analyzing the measured response data, the modal properties of the structure can be extracted.

Click here to read more on Impact-Synchronous Modal Analysis (ISMA)

Operational Deflection Shapes

ODS analysis is a technique used to visualize and analyze the vibration patterns or deflection shapes of a structure during its operational state. It involves measuring the structural response while the structure is subjected to operational loads or excitations, such as machinery vibrations or environmental forces. ODS analysis helps identify areas of excessive deformation or vibration amplitudes, allowing engineers to assess the structural integrity and performance under dynamic conditions.

Case Study - Canned Motor Pump

The Problem

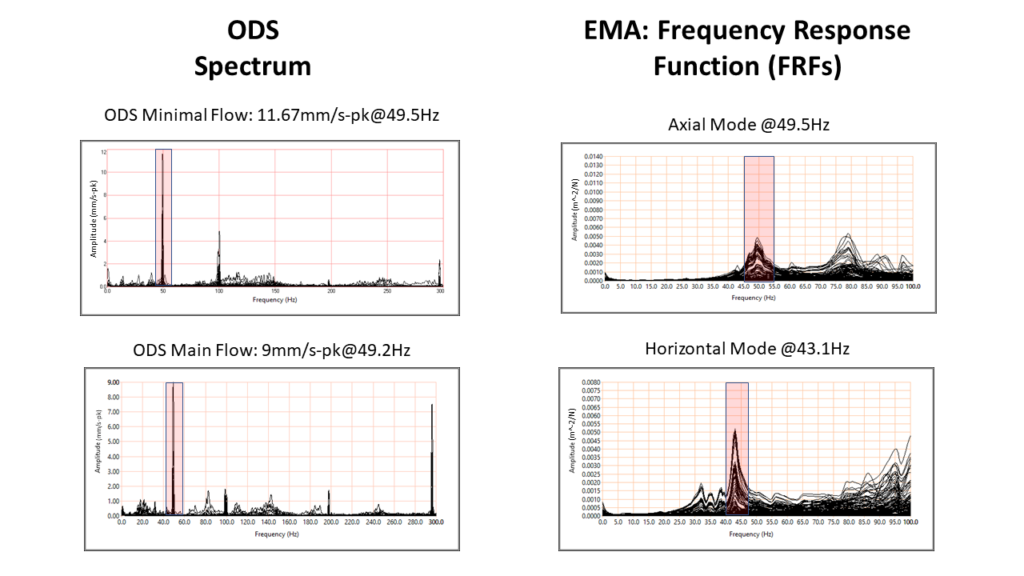

Through ODS, high vibration was observed at the canned motor pump at its 1x running frequency (49.2Hz/49.5Hz) during minimal and main flow.

When EMA was performed, it was found that there were structural modes coincided/near the 1x running frequency. This could explain why high vibration was observed during operation.

The shapes were extracted and compared as below:

It was observed that the operating deflection shapes of the pump during 1x running frequency are similar to its structural mode shapes at 43.1 Ha and 49.5Hz. Based on the shapes, it was found that the pump was dynamically weak in axial, horizontal, and vertical directions near the base plate. Therefore, structural dynamics modification (SDM) was recommended to strengthen the base plate and to shift the modes away from the running frequencies.

Click here to read more on SDM performed for this case study:

Past Projects

- Operating Deflection Shape Analysis, Modal Analysis and Structural Dynamic Modification of P-102A & B Canned Motor Pump Package, Petronas Chemical Isononanol (PC INA), Johor, 19 September 2022

- Operating Deflection Shape Analysis, Modal Analysis and Structural Dynamic Modification of P-2320A Hydro Recycle Pump Package, BASF Petronas Chemicals SDN BHD, Pahang, 19 May 2022

- Operating Deflection Shape Analysis and Modal Analysis of K-3003 Motor-Compressor-Vessel Package, PC MTBE SDN BHD – PDH PLANT, Pahang, 27 April 2022

- Modal Analysis of UT-0-K-201A Air Compressor Spare Pinion Shaft with Impeller, Petronas Chemicals Polyethylene Sdn Bhd, Kerteh, Terengganu, 7 March 2022

- Operating Deflection Shape Analysis and Modal Analysis of Canned Motor Pump 3610-P-501 and 3610-P-601, Petronas Chemical Isononanol (PC INA), 9 March 2022

- Operating Deflection Shape Analysis, Modal Analysis and Structural Dynamic Modification of RU-9060 Chiiled Water Unit, BASF Petronas Chemicals SDN BHD, Pahang, 25 February 2022

- Operating Deflection Shape Analysis and Modal Analysis of Canned Motor Pump 3610-P-203A/B/C, 3610-P-207A/B, 3610-P-206, 3610-P-501, Petronas Chemical Isononanol (PC INA), 22 November – 3 December 2021

- Operating Deflection Shape Analysis and Modal Analysis of Z-4601 Vapor Recovery Package, KPOC – Platform KBB Sabah, 18 November 2021

- Operating Deflection Shape Analysis and Modal Analysis of KG-2020 HP Gas Expander Induction Generator, PC MTBE SDN BHD – PDH PLANT, Pahang, 12 July 2021

- Operating Deflection Shape Analysis and Modal Analysis of Dynamic Diesel UPS unit no. 3&4, X-FAB Sarawak, Kuching, Sarawak, 3 June 2021

- Modal Analysis of UT-0-K-201A Air Compressor Pinion Shaft with Impeller, Petronas Chemicals Polyethylene Sdn Bhd, Kerteh, Terengganu, 10 May 2021

- Modal Analysis of UT-0-K-201A Air Compressor Structural Casing, Petronas Chemicals Polyethylene Sdn Bhd, Kerteh, Terengganu, 3 May 2021

- Modal Analysis of UT-0-K-201A Air Compressor Pinion Shaft, Petronas Chemicals Polyethylene Sdn Bhd, Kerteh, Terengganu, 19 April 2021

- Post-processing of EMA and ODS site-measurement data of P-8301, P-8302, P-8303 Fire Water Pumps, XAIR Energy Sdn Bhd, 22 October 2020

- Post-SDM Modal analysis and Operating Deflection Shape analysis of P122-A 2nd Reactor Outer Cooler Pump, Petronas Refinery and Petrochemical Corp (PRPC) / TecnimontHQC, 13 October 2020

- Post-SDM Modal analysis and Operating Deflection Shape analysis of P202 Stage I Dimerization Emergency Pump, Petronas Chemical Isononanol (PC INA), 25 September 2020

- Modal analysis of EA1702AA Cooler Fan, MTBE, Petronas Chemical MTBE Sdn Bhd, 30 July 2020

- Modal analysis of P-202 Stage I Dimerization Emergency Pump and P103A & P-103B Circulation Pumps, Petronas Chemical Isononanol (PC INA), 2 July 2020

- Experimental Modal Analysis of 6 Stage Vertical Suspended Pump Rotor, Flowserve Solutions (Malaysia) Sdn. Bhd., Kuantan, 31 January 2019

- Experimental Modal Analysis of Atomization Air Blower K-39-01, Petronas Chemicals Fertilizer Kedah, 17-18 December 2018