Universiti Malaya Engineering Structural Health Monitoring

What is Structural Health Monitoring (SHM) and why is it necessary?

SHM BACKGROUND

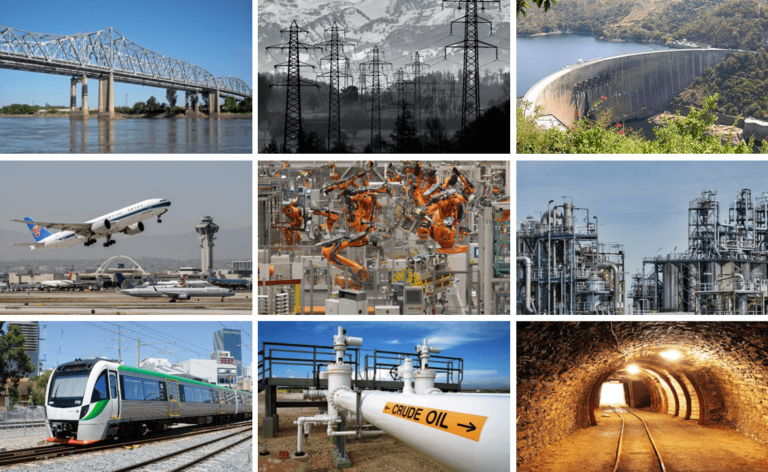

Advanced, large, and expensive structures and infrastructures such as buildings, bridges, dams, oil platforms, offshore structures, piping systems, railways, etc. are designed to last long. However, many of them are more than halfway through their intended service life, and some of them have already reached the end of it. Therefore, they are considered structurally deficient, meaning they are in “poor” condition and in need of maintenance that requires spending billions.

Structures

Infrastructure

Railways

Energy

Oil and Gas

Ports

Roads

Airports

Pipelines

Healthcare

Damage:

Changes in:

- Geometric properties;

- Boundary conditions;

- System connectivity;

- etc…

Failure Statistics:

Factors leading to Extensive Degradation:

- Fatigue, Aging

- Corrosion, Delamination, Wear, Creep

- Environmental effects (e.g., micro structural defects, cracking, thermal stress, residual stress, instability, and fastening or adhesive faults)

- Overloading, changes in loading patterns

- Unexpected causes such as wind excitations, earthquake, vehicle impact or blast loads

Structural Health Monitoring - A Transdisciplinary Field

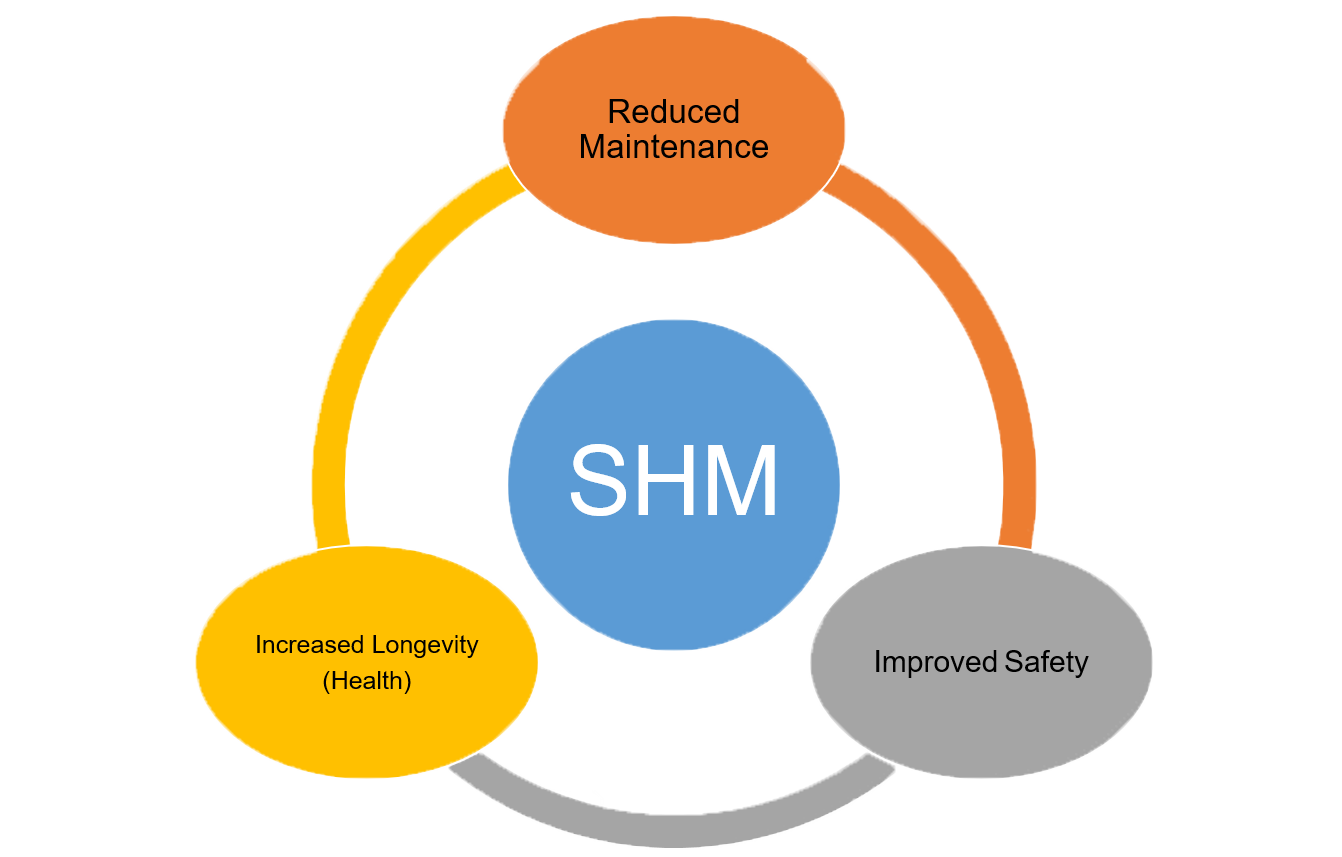

Structural Health Monitoring (SHM) is the observation and analysis of engineering assets to monitor changes to the material and geometric properties. Early detection of damage is one of the most important factors in maintaining the integrity and safety of structures. However, conventional Structural Health Monitoring (SHM) approaches are challenged by real-time, low-cost and quality-guaranteed SHM.

Aims of SHM:

- To determine the current condition

- To predict future behavior

- To detect early structural damages

Diagnosis Levels:

- Level ❶: Damage Presentation

- Level ❷: Damage Localization

- Level ❸: Damage Extension

- Level ❹: Service life Prediction

Functionality of SHM Systems

The latest technologies, i.e. data analytics, Artificial Intelligence (AI), blockchain, Impact-Synchronous Modal Analysis (ISMA), and Technology Acceptance Model (TAM) need to cope with such bottlenecks to act more cost-effectively and sustainably in the planning, control, and management of engineering assets by providing high Health, Safety, Environment, and Quality (HSEQ) to prolong their life cycle.

Smart SHM as a powerful tool can be significantly used to mitigate the aforesaid concerns. This is also aligned with the Industrial Revolution 4.0 (IR 4.0) which promotes robotics and AI in research and analytics to industries and organizations in predictive policing.